This is the second half of the Plane Till and Gallery build. I started this whole project as part of my build out on my free-standing tool chest. And there’s been a lot of input on this from various people at Lumberjocks, Sawmill Creek, and WoodworkingTalk. If you haven’t visited those websites I would recommend it, there’s some absolutely amazing people contributing there.

With the lower cabinet and upper casework done, I’m focusing on the Plane Till portion, and this is the part of this build that actually holds my #3 through #6 planes.

When I started woodworking years ago I could not get a hand plane to work. After many years I finally found out the reason was that the planes were not sharp. Once you get a hand plane sharp it’s an absolute joy to use. I have several from my father and added to that collection. One thing I discovered is that for me a Bailey #5 the answer to about 60% of my planning. The next most used plane for me is probably my Bailey #4 1/2 . And of course, there are my block planes that are easy to pick up and use just about any time.

Second, only to not having sharp planes, is not having access to planes. And while I have quite a few, having them close to hand has always been a big problem. They usually sit on shelves or are buried under something, and I can’t find them or can’t easily access them. That means I don’t usually grab them. Which leads to the purpose of this whole Plane Till and Gallery project, and that is to provide easy access so I can use the planes whenever I choose.

This Plane Till project has been designed around the planes that I have so if you’re going to use the dimension sketch please make sure the dimensions suit the planes that you have. This may require you adjusting various dimensions to make it work. Hope you get something out of this and follow this link to my Video to see how it is done.

Tools and Materials

Materials are pretty straightforward because it’s a very straightforward project. You’re going to need 2 pieces, one for each of the uprights left and right, around 30 inches long and about 6 1/2 inches deep. You’ll need a piece for the base which is going to be 21 by 24 and a series of battens there are 3/4 inch by 5/8 inch. And of course, screws to screw everything together.

The only specialty tool that you really need here or could use is a power planer. A power player will make short work of creating the touchdown angle at the top of the backboard.

Layout

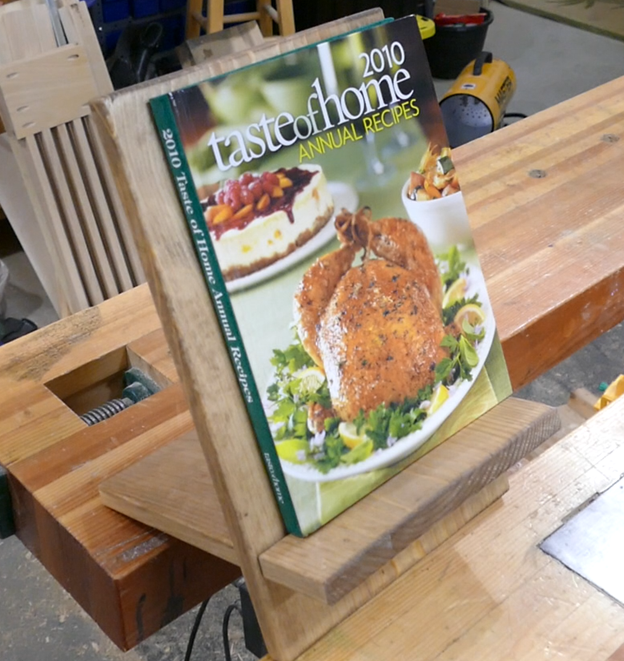

Your initial layout is going to be for the angle on both of the sides. If you’re using a jig as shown in the picture all you really need to do is make the measurement marks on the edges. For the rounded cut out there is nothing special. A three-inch coffee cup or larger can be used to create the arc. The biggest effort for layout is going to be positioning the battens for the planes. You’ll do this individually by hand and then mark and cut each one.

Cutting

Your first cut is going to crosscut the side pieces to length. Next, cut the angle on each of the sides left and right. If you use the jig shown in the picture all you need to do is to mark the edge And clamp the piece in the jig at the marks. Using the job will make this highly repeatable. If you don’t have a jig like this Rockler makes one for a very reasonable price.

You will also need to cut the base to size.

Cutting the Relief

With the pieces cut to length and the angles cut, your next step is to cut the relief on the left-hand side. This is nothing more than a 3 1/2-inch quarter radius. You could mark it out with a can or a cup or you can use a compass. Once it’s marked, take it to the bandsaw or use a jigsaw or coping saw and make the cut.

Forming the Top Angle

No pictures but use the dimensions to strike to bottom line of the angle. Then with a hand plane or power plane remove material from the edge to the line. DO NOT TRY TO USE A TABLE SAW!

Sanding

Sand all the flats surfaces with 220 grit sandpaper and be sure to remove any burn marks from the sawing process.

You will need to sand the angle too .

More Cutting and Sanding

Next you’ll need to cut the battens. Generally, these need to be 3/4″ x 5/8 inch by two feet long. You will need to cut 14 to 18 of these depending on how many planes you have. Be sure you sand these pieces and round the edges on one side. Or. you can run these through a router with a 1/8” round over bit.

Finishing

I used boiled linseed oil as the finish on mine and I highly recommend it though you can use varnish or lacquer. Apply the finish to all parts. We’re not using glue so it doesn’t matter that everything is finished. We’re depending solely on screws to hold everything together.

Assembly

Assembly is pretty straightforward. Start by screwing the right side to the case and then screw the left side to the plane gallery. (Make sure the Plane Gallery is screwed in place!)

While the base is laying on your bench, screw down the lower batten and upper batten. With those in place set each plane down where you want it and screw down the separating batons between each. You may want to cut the battens down in length and put cross patterns in to hold the planes. I would also use one screw at the bottom for each plane. You probably don’t need to do this but it looks really good. So honestly it’s more of a decoration after the first four.

With all the battens in place remove the left and right batten and the top batten. Place the assembly in position and screw it down. This will require about 3 screws on each side plus another one or two screws to the top. Finally screw the top, left, and right battens in.

Finished

Well, the project is done and you can put your planes in place. I hope you take the time to make this project because it will help organize your shop and make creating things much more fun.

If you do make this project, congratulations on a job well done. And do me a favor and post it on my Facebook page (see link below).

Hope you got something out of this and if you did, do me a favor, hit like and subscribe. I’d appreciate that a lot.

Thanks for reading and until next time Good Making!

Bill

Visit my Etsy Store at www.etsy.com/shop/30MinuteWoodshop

Facebook https://www.facebook.com/30MinuteWoodshop

Links to my Videos and Blogs

Create Your Own Dice Vault https://30minutewoodshop.com/?p=1226

DIY Whiskey and Cigar Butler https://30minutewoodshop.com/?p=550

Farmhouse Key Rack https://youtu.be/I65FGq4dKYY

Create Your Own Lazy Susan https://30minutewoodshop.com/?p=491

Tools and Materials you may need

Rigid Oscillating Belt Sander https://amzn.to/45C3rTK

Starrett Combination Square https://amzn.to/3XpbrDN

WoodRiver Low Angle Block Plane https://amzn.to/3pkNvos

Milwaukee M18 Jig Saw Kit https://amzn.to/3FAWXsS

BOSCH Compound Miter Saw https://amzn.to/421A1vl

Minwax Fast Drying Polyurethane https://amzn.to/3V5h0pO

PPE Gear